PRODUCTS

18690011071

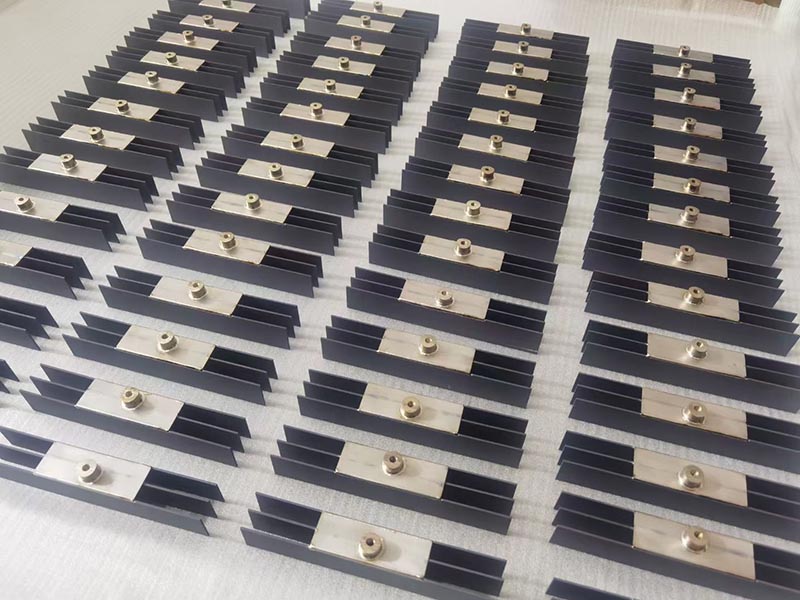

Titanium anode for electroplating

1. Application areas: Electroplating of zinc and precious metals (including gold plating, silver plating, palladium plating, etc.); Electroplating hard chromium; Electroplating nickel; Electroplating tin (tin plating on steel plates).

2. Coating type: Titanium based ruthenium iridium titanium based iridium tantalum titanium based platinum

3. Comparison of superiority with conventional lead anodes for electroplating

1) Low slot voltage and low energy consumption

2) The rate of electrode loss is small, and the size is stable

3) The corrosion resistance of the electrode is good, and its insolubility does not pollute the tank solution, making the performance of the coating more reliable.

4) The titanium anode adopts new materials and structures, greatly reducing its weight and facilitating daily operations

5) Long service life and reusable substrate, saving costs

6) The overpotential of oxygen evolution is about 0.5V lower than that of insoluble lead alloy anodes, which reduces the tank voltage and energy consumption.

5. Electrochemical performance and life testing (refer to standard HG/T2471-2007 Q/CLTN-2012)

name

Strengthening weight loss mg

Polarization rate mv

Oxygen evolution/chlorine potential V

Test conditions

Titanium based iridium tantalum

≤ 10

< 40

< 1.45

1mol/L H2SO4

Titanium based ruthenium iridium

≤ 10

< 40

< 1.13

1mol/L H2SO4

Titanium based platinum

≤ 1

< 40

< 1.75

1mol/L H2SO4

6. Product usage background and introduction:

In the field of electroplating applications, the required coating metal is dissolved in the electrolyte, and the plated metal substrate serves as the negative electrode, while the anode serves as the positive electrode, forming a complete current transmission cycle. The chemical reaction that occurs simultaneously with electroplating in the electroplating tank is the precipitation of oxygen on the anode surface.

Compared to non inert anodes such as graphite, the advantage of titanium anodes is that they can maintain a stable distance between the positive and negative electrodes (electrode to electrode distance) throughout their service life. Graphite anodes will gradually dissolve during use, leading to an increase in distance between electrodes, while inert titanium anodes can ensure stable voltage and product quality. Due to the catalytic properties of platinum group elements, the exchange current density on the electrode surface is high, the overpotential for oxygen precipitation is low, and a special process is used to create a micro structured oxide film on the titanium surface, obtaining a large active surface area per unit electrode area. Therefore, it is particularly suitable for high-speed and high current density electroplating production.

In addition to titanium anodes and graphite, lead anodes can also be used in this field. However, when the lead anode dissolves, its reactants will have a negative impact on the environment. These issues can be avoided by using titanium anodes. The working voltage of the titanium anode for oxygen evolution is relatively low, which can also play a role in energy conservation.

Another advantage of using titanium anodes is that the titanium substrate can be reused. When the lifespan of the titanium anode coating reaches its service life, anodized aluminum foil is a commonly used material in the offset printing industry. The original purpose of their work